Electric Swivels from Onboard Systems Help Improve Safety for Rotating Loads

Sunday, December 15, 2013

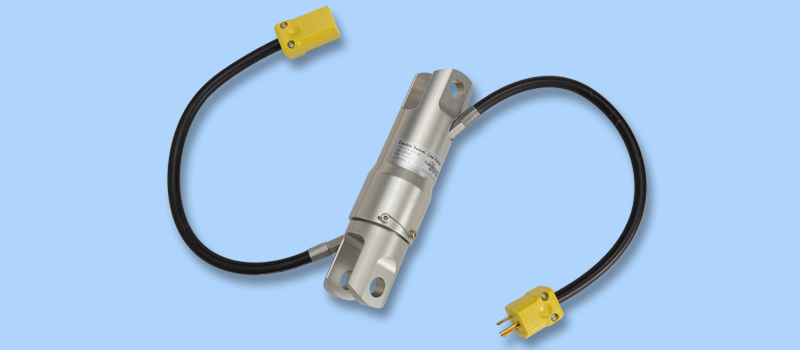

Onboard Systems has designed and manufactured a growing line of electric swivels to enhance flight safety for external load missions transporting spinning loads. Electric swivels provide a continuous electrical connection between the cockpit release and the remote cargo hook, while allowing for hook rotation to accommodate external load movement without curling or tangling of the long line.

Current electric swivel models include load capacities ranging between 2,000 to 6,000 LB (907 to 2,722 KG). These products include many safety and durability features, such as stainless steel housing for the swivel body, stainless steel braid for the electric cables, and easy linkage couplings. They also include a built-in travel stop that mounts directly on the lugs of Onboard's TALON® brand Remote Cargo Hooks to limit rotation and prevent damage to the electrical cable.

"The recent FAA SAFO regarding Part 133 external load operations with spinning loads discusses the safety advantage that swivels can provide when performing external load work," said Karsten Lemmon, Vice President of Sales & Marketing for Onboard Systems. "That is why Onboard created a robust, safety-focused line of electric swivels that works with our TALON® remote cargo hooks—as well as other brands—to ensure that the greatest number of operators would have access to this important safety equipment."

On November 4, 2013, the FAA issued a safety alert for operators (SAFO 13010) to outline current guidance and best practices for Part 133 external load operators that discusses the importance of using a swivel so that spinning loads do not affect flight safety. The precautions are especially important when rigging loads (or load configurations) that are new to the operator—particularly those known to rotate. The document also recommends that Part 133 operators train pilots and ground personnel thoroughly and conduct briefings before each operation begins.

"Onboard's electric swivel line was designed to satisfy the need for robust, durable swivels that will function well in a wide variety of environmental conditions, while also providing extra protection for the electrical harness," said Karsten Lemmon, Vice President of Sales & Marketing for Onboard Systems. "Our swivel design incorporates key input from many of our worldwide customers and reflects the very latest safety innovations available."

Onboard's electric swivel bodies are made of 100% stainless steel to ensure years of trouble-free use in a wide variety of environments. The entire length of both electrical cables is sheathed in stainless steel braid and includes robust strain relief at the cable ends, protecting them from damage during operation and minimizing the potential for breakage. Both ends of the swivel include attachment bolts and nuts that allow it to connect directly to the long line and the remote cargo hook.

For more information about Onboard's electric swivels, please click here.

Tags

Vol10-Iss4electric swivelssafo 13010More Articles

Tracking Water Drops

How to use the C-39 cockpit indicator to track water drops for contracts.

Return for Service Shipping Tips

International "Return for Service" shipments can be tricky. Here are some tips.

How to Upgrade Your Equipment

We strive to make it simple and cost-effective for our customers to upgrade their equipment.

Get the 411 on Surefire Products

Here is a complete reference list of aircraft and cargo hook kits currently featuring Surefire.

Documentation Updates

Get the 411 about all the documentation updates and service bulletins that have taken place since the last issue.

Send Us Your Photos & Videos

If you've got some great helicopter photos or videos of helicopters at work, we'd love to hear from you!