Shop Talk: Nut Adjustments to Load Cell Covers

Thursday, May 23, 2019

Recently we've noticed a number of link-style load cells coming in for repair where the nuts that secure the covers have been treated with Glyptal or similiar protective coatings. The coating itself is not a problem, but we've also noticed that the nuts appear to have been tightened prior to the application of the coating — and that is a problem.

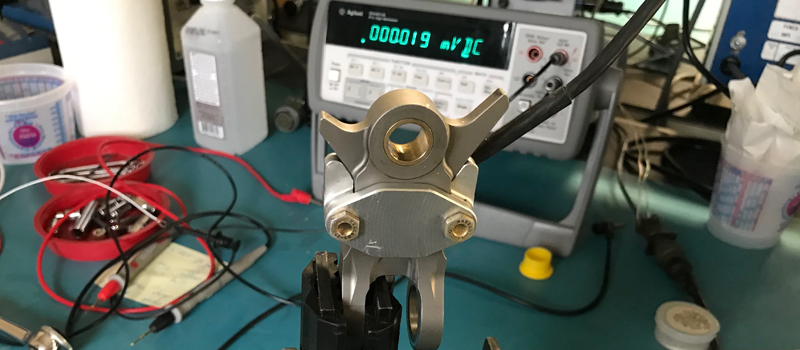

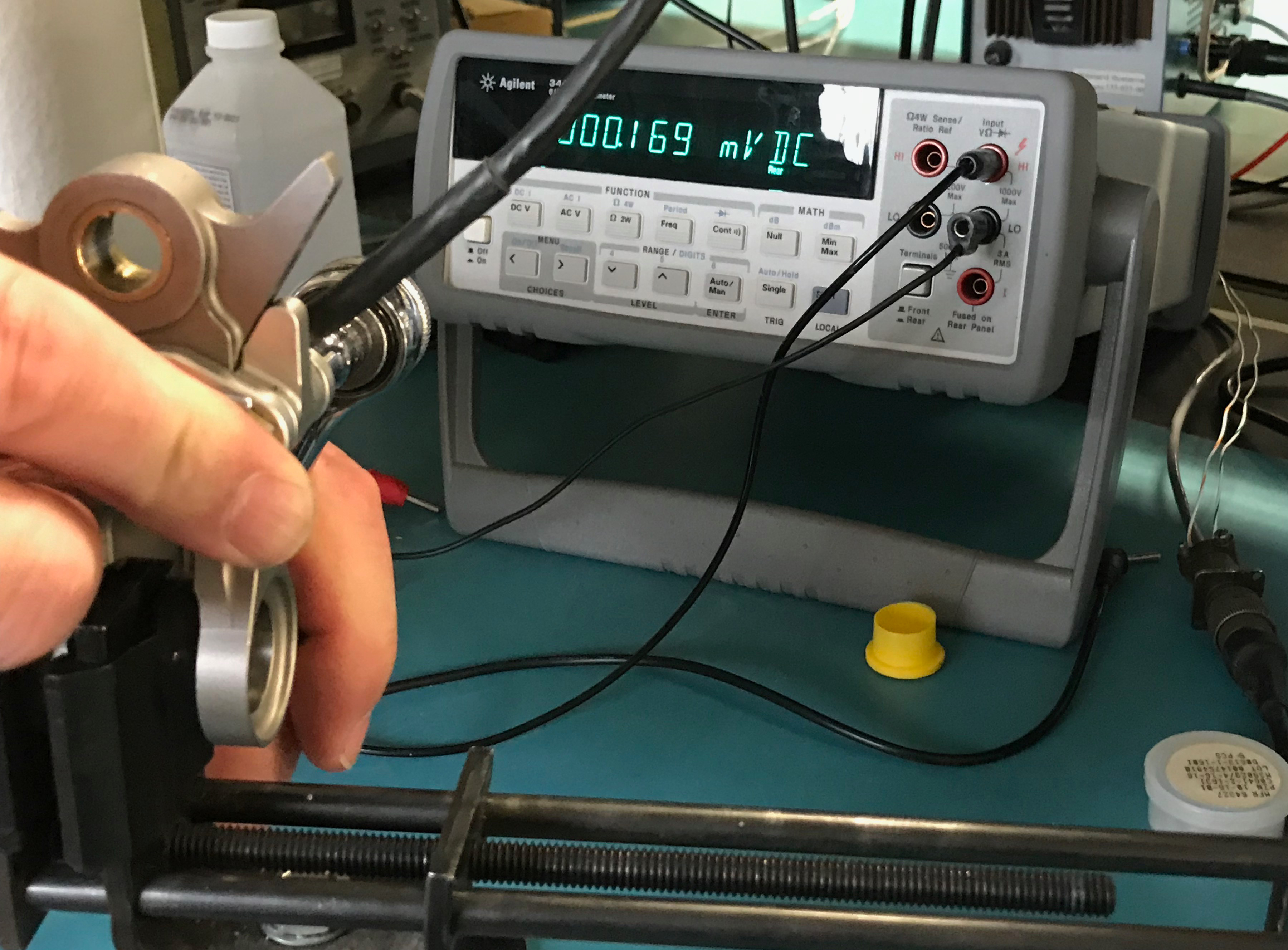

The photos for this article demonstrate what happens when a nut on a load cell is adjusted. The photo at the top of the page shows a load cell that has been calibrated for optimal weight accuracy. In the second photo, a technician demonstrates that even a gentle torque with a wrench changes the reading, diminishing the accuracy of weight measurements. Further adjustments to the nuts could cause the load cell to fail altogether.

Onboard Systems uses locking nuts on all of our load cells, which are carefully calibrated and balanced by our factory technicians to ensure the highest load weight accuracy possible. That means that the nuts may or may not be fully tightened against the load cell body; they are tightened only to the point of highest accuracy. They should not be tightened, loosened, or manipulated in any way by the end user after factory balancing.

If the nuts are tightened, loosened, or otherwise manipulated by the operator, not only will the weight-measurement capabilities of the load cell be thrown off, the unit may simply stop functioning — requiring factory service.

If you are operating your Onboard Weighing System in a harsh environment, such as marine or desert conditions, and wish to apply Glyptal or a similar protective coating to the load cell, simply refrain from adjusting the load cell nuts prior to applying the coating. It may go against your instincts to check and tighten all nuts, but remember the nuts are locking and they will not fall off during normal operating conditions, even if they don't appear to be fully tightened.

In addition, our load cells are manufactured from corrosion-resistant materials, such as stainless steel, and don't need to be coated to ensure long life. Simply follow the maintenance guidelines provided in your owner's manuals, and lift with confidence!

If you have any questions about caring for your Onboard Weighing System, feel free to reach out to one of our technical support representatives by phone or email, or through our online support form.

Tags

shop talkload cellsMore articles

Inspection Schedules

Get the 411 on required inspections and maintenance intervals for your cargo hook.

C-40 Firmware Updates

Here's what you need to do to upgrade the firmware on your C-40.

Changes to Load Cell Maintenance

We revised the maintenance criteria for our Onboard Weighing Systems.

Load Cell Nut Adjustments

Don't torque that nut! Here's why you should never adjust the nuts on your load cells.

Fix It Yourself, or Return for Service?

There are times when you should contact us before working on your equipment.